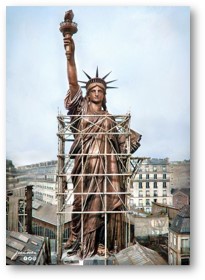

The Statue of Liberty

and Intercept Technology

The Liberty Intercept name was chosen for two reasons. First and foremost, our major product line was a serendipitous artifact of the Statue of Liberty restoration John Franey (pictured below) of Bell Labs invented Intercept Technology™.

The Liberty Intercept name was chosen for two reasons. First and foremost, our major product line was a serendipitous artifact of the Statue of Liberty restoration John Franey (pictured below) of Bell Labs invented Intercept Technology™.

Prior to his Intercept Technology™ invention, Franey had been a lead copper corrosion engineer in the Statue of Liberty restoration project.

Franey developed a uniform patina seeding transplantation process for Lady Liberty, to be applied on the replaced copper panels.

In a matter of weeks, the clean copper panels were transformed into copper panels with a magnificent natural patina green. This patina typically takes thirty years of natural aging to color. A new class of materials called Intercept Technology™ was invented by seeding reactive ions (copper in this case) into various chemical structures.

The second reason is that utilizing the Intercept Technology™ packaging materials allows folks the “liberty” to ship and store products anywhere, safely. Oil-free corrosion control for all materials.

And Intercept Technology continues to innovate. Coming soon to the US market: Corrosion Intercept filters and facemasks. Contact us for further information.

Photo of Lady Liberty courtesy of History.org.