Discussion: CHIPS Act - Bring it Home

"Nothing is more expensive than a closed mind, and a missed opportunity". - H. Jackson Brown, Jr., American Author

The US government made an unprecedented move by funding the U.S. semiconductor industry via The CHIPS Act. Of course, they have been involved in transportation, defense, energy, and other industries, but the Chips Act is different. How the U.S. disburses the CHIPS funds is key to success. It is essential to organize this taxpayer investment correctly and not overburden funding requirements with too much regulation.

The US government made an unprecedented move by funding the U.S. semiconductor industry via The CHIPS Act. Of course, they have been involved in transportation, defense, energy, and other industries, but the Chips Act is different. How the U.S. disburses the CHIPS funds is key to success. It is essential to organize this taxpayer investment correctly and not overburden funding requirements with too much regulation.

As discussed in a previous post, for years the United States lost ground in chip and board manufacturing, losing 25% of market share since 1980. The situation is similar to the bag-making business that Liberty is familiar with, in which Asian companies captured large portions of the business, almost exclusively with high-volume sales. Because of that shift, these manufacturers were able to fund and install the most modern equipment, with tighter tolerances than that of American companies. As a consequence of loss of sales to overseas producers, many smaller U.S. companies have been unable to afford expenditures for more sophisticated bag-making equipment.

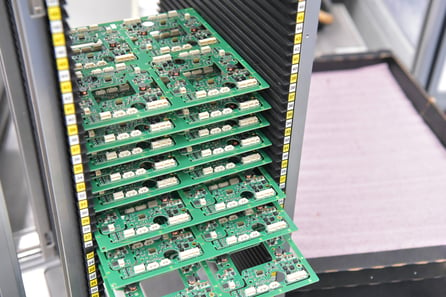

With the CHIPS Act commitment, particularly in the printed circuit boards (PCB) realm, American manufacturers will be able to dedicate these funds to manufacture of the more advanced, smaller, higher-capacity boards. This advance would result in a greater number of U.S. manufacturers being able to sell competitively into other lucrative markets such as security, communications, medical, and energy, while depending less on DoD purchases.

As always, the new suppliers on the block will be the most scrutinized for quality. The worldwide increase in capacity will not stop current manufacturers from producing and competing. It is projected to be a growing market but competition may be fierce initially, and getting over this hurdle requires thoughtful planning. The success or failure of this opportunity lies in the balance.

This drive for miniature, ever more condensed electronics will mean that corrosion and electrostatic discharge (ESD) will be even more important to avoid. Intercept Technology barrier packaging products solve these problems, so that the quality of the product placed remains intact. It is essential that best practices in all aspects of these new manufacturing processes should be explored and met, including shipping and storage packaging. Old methods and materials may not be up to the task.

Intercept protection is the best. Here’s why.

- For ESD concerns, Static Intercept has a turn on potential of less than one volt. That means Static Intercept can protect the most sensitive devices, class 0 (susceptible to damage from volts 1-50), like no other packaging. Static Intercept is permanently static dissipative without any concern to loss of quality or function, no matter the environment.

- Static Intercept and RIBS are made of solid state materials and do not contain chemical additives. They are clean without contamination to devices and boards placed inside.

- Static Intercept and RIBS will stop corrosion. The industry uses topical coatings to prevent corrosion but they are imperfect and not as robust as Intercept packaging. Gaps in coatings can be infiltrated by atmospheric gases and with the smaller leads and traces, even a small bit can cause defects or worse, could cause “walking wounded”, such as electrical overstress.

- Static Intercept is a mono-layered polyethylene so it meets all the foreign directives for recycling and reuse.

- Intercept Technology products are USA-made.

We offer this relevant Intercept Technology case study: A large scanning equipment manufacturer to the chip manufacturers, buys Static Intercept sheets which they wrap their PCBs into. These PCB’s are either placed into storage as replacements or shipped to assembly for installation. For the replacement boards, after the technician makes the replacement, the old board are shipped in the same packaging for analysis. That way both the replacement and the replaced boards stay clean and safe in storage and transport. The expected whole life is met and quality analysis remains true.

Choose Static Intercept Stock Bags for quick availability.

Liberty Intercept Blog

CHIPS Act, Part III: Plan for Success

Posted by Joe Spitz on Feb 15, 2023 5:03:34 PM

Discussion: CHIPS Act - Bring it Home

"Nothing is more expensive than a closed mind, and a missed opportunity". - H. Jackson Brown, Jr., American Author

As discussed in a previous post, for years the United States lost ground in chip and board manufacturing, losing 25% of market share since 1980. The situation is similar to the bag-making business that Liberty is familiar with, in which Asian companies captured large portions of the business, almost exclusively with high-volume sales. Because of that shift, these manufacturers were able to fund and install the most modern equipment, with tighter tolerances than that of American companies. As a consequence of loss of sales to overseas producers, many smaller U.S. companies have been unable to afford expenditures for more sophisticated bag-making equipment.

With the CHIPS Act commitment, particularly in the printed circuit boards (PCB) realm, American manufacturers will be able to dedicate these funds to manufacture of the more advanced, smaller, higher-capacity boards. This advance would result in a greater number of U.S. manufacturers being able to sell competitively into other lucrative markets such as security, communications, medical, and energy, while depending less on DoD purchases.

As always, the new suppliers on the block will be the most scrutinized for quality. The worldwide increase in capacity will not stop current manufacturers from producing and competing. It is projected to be a growing market but competition may be fierce initially, and getting over this hurdle requires thoughtful planning. The success or failure of this opportunity lies in the balance.

This drive for miniature, ever more condensed electronics will mean that corrosion and electrostatic discharge (ESD) will be even more important to avoid. Intercept Technology barrier packaging products solve these problems, so that the quality of the product placed remains intact. It is essential that best practices in all aspects of these new manufacturing processes should be explored and met, including shipping and storage packaging. Old methods and materials may not be up to the task.

Intercept protection is the best. Here’s why.

We offer this relevant Intercept Technology case study: A large scanning equipment manufacturer to the chip manufacturers, buys Static Intercept sheets which they wrap their PCBs into. These PCB’s are either placed into storage as replacements or shipped to assembly for installation. For the replacement boards, after the technician makes the replacement, the old board are shipped in the same packaging for analysis. That way both the replacement and the replaced boards stay clean and safe in storage and transport. The expected whole life is met and quality analysis remains true.

Choose Static Intercept Stock Bags for quick availability.

Topics: American manufacturing, manufacturers, electronics packaging, Semi-conductor

Related Posts

Contamination Testing

Packaging's Crucial Role vs FOD

Customer Service with a Smile

Leave a Comment